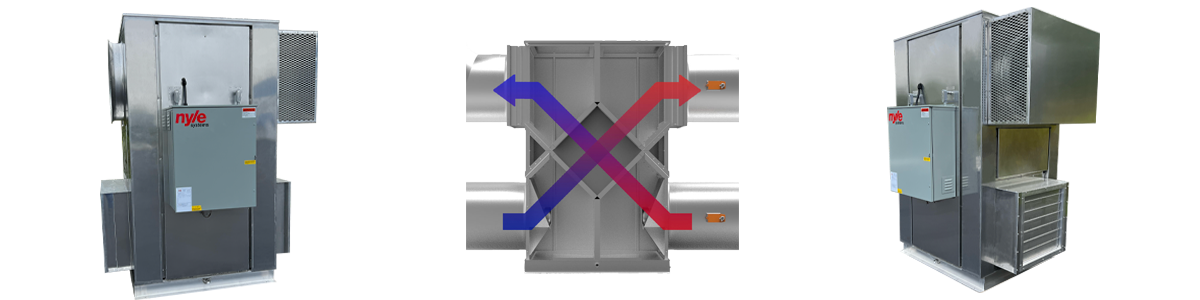

At Nyle, we understand the challenges kiln owners face with energy loss during lumber drying. Our groundbreaking HRV (Heat Recovery Vent) technology is designed to capture and reuse the heat typically lost through venting, ensuring your operations are more efficient, cost-effective, and environmentally friendly.

Significant Energy Savings: Recover over 80% of lost heat, reduce fuel consumption by at least 15%, and save you money on energy costs.

Optimized for All Seasons: Whether it's winter or summer, the HRV 5000 model adjusts to save you the most energy, with capacities of 305,502 BTU/hr and 116,568 BTU/hr, respectively.

Powerful Venting Capacity: With a venting capacity of 5000 CFM, our HRV systems ensure optimal drying conditions for your lumber, accommodating slow-drying hardwoods to fast-drying softwoods.

Improved Wood Quality: Better energy management results in a more consistent drying process, leading to superior wood quality and reduced degradation.

Flexible Installation Options: Whether you're setting up a new kiln or retrofitting an existing one, our HRV system integrates seamlessly, ensuring minimal downtime and maximum performance.

Join countless kiln owners who have already embraced Nyle's heat recovery vents to revolutionize their lumber drying process. Take the first step towards enhanced efficiency and sustainable practices in kiln drying. Embrace the future of lumber drying with Nyle today!