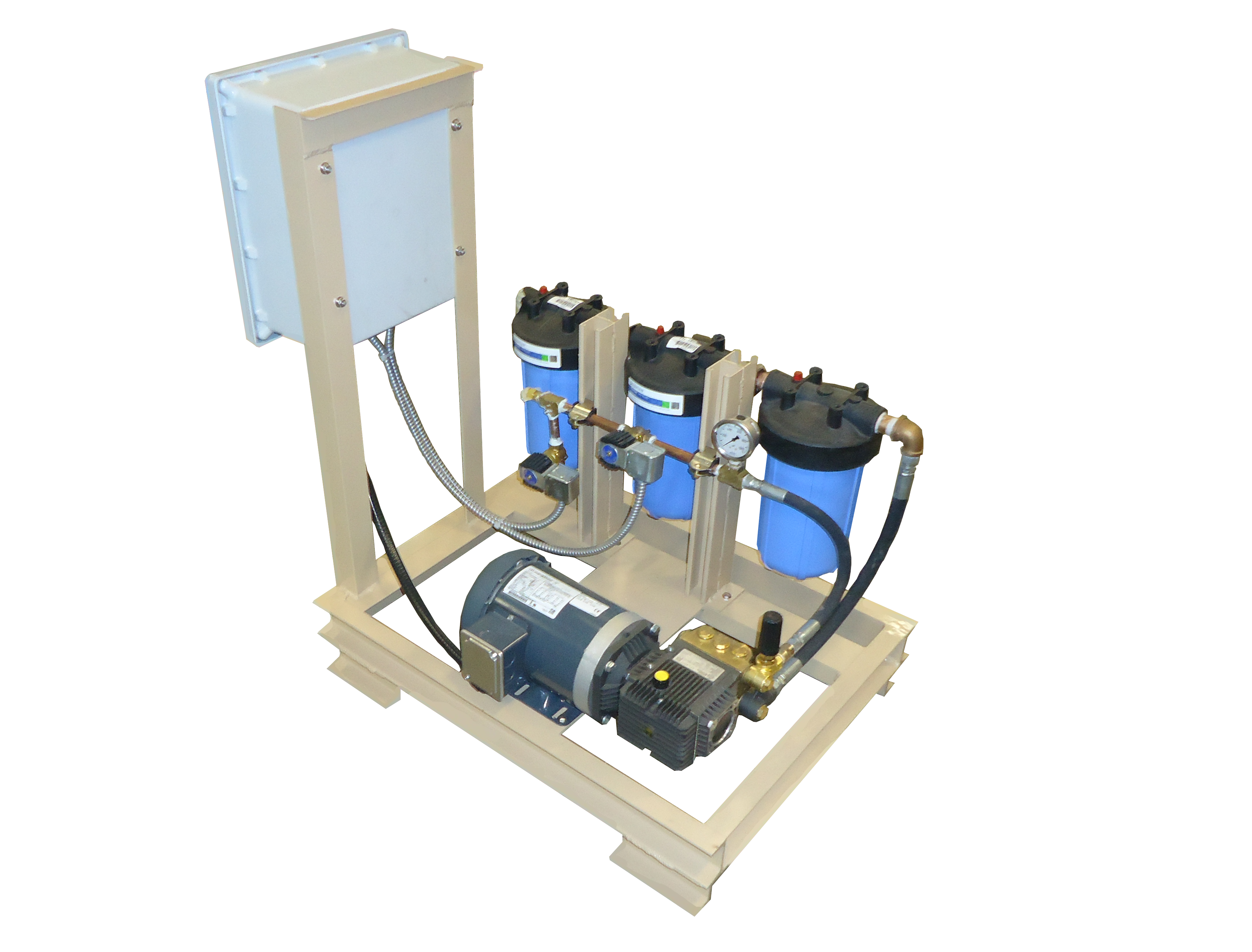

Nyle introduces an Atomizing Spray System designed to enhance the humidity control within kiln chambers, pivotal for the lumber drying process. This system ingeniously adds moisture back into the air, aiding in precise humidity management and wood conditioning at the drying cycle's end. It's an innovation aimed at improving wood quality by mitigating stress caused by drying.

Optimal Humidity Control: Achieve precise relative humidity levels for each wood load, preventing rapid moisture loss that could compromise wood quality.

Enhanced Wood Conditioning: Reintroduce moisture at the drying process's end to reduce wood stress, ensuring a superior finish.

High-Pressure System: Increases wet bulb temperature while minimizing boiler dependency, chemical use, and water makeup needs.

Efficient Water Flow: 3.5 GPH per nozzle at 500 PSI.

Versatile Nozzle Configuration: 5-10 nozzles per kiln bay, adaptable to your specific needs.

Broad System Capacity: Designed to serve two kilns, doubling efficiency.

Compact and Powerful: A robust 3 HP motor housed within a space-efficient design of 40" W x 24" D x 38" H and weighing 150 lbs.

Electrical Requirements: 480 V three-phase, 60 Hz, 15 A, ensuring easy integration into existing systems.

Nyle's Atomizing Spray System is not just an addition to your kiln; it's a strategic upgrade designed for efficiency, sustainability, and exceptional wood quality. Embrace the future of kiln drying today with a system built to last and perform.