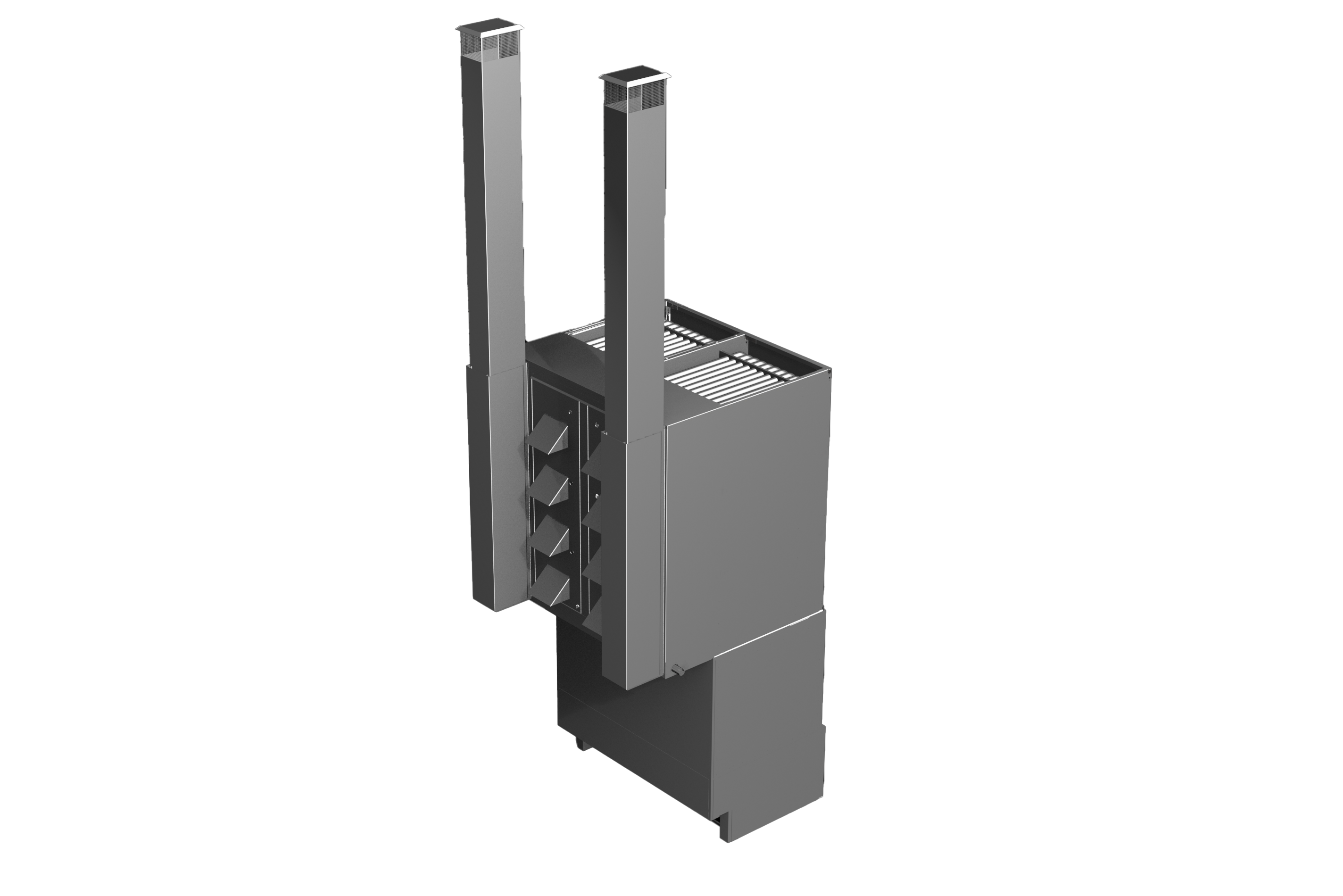

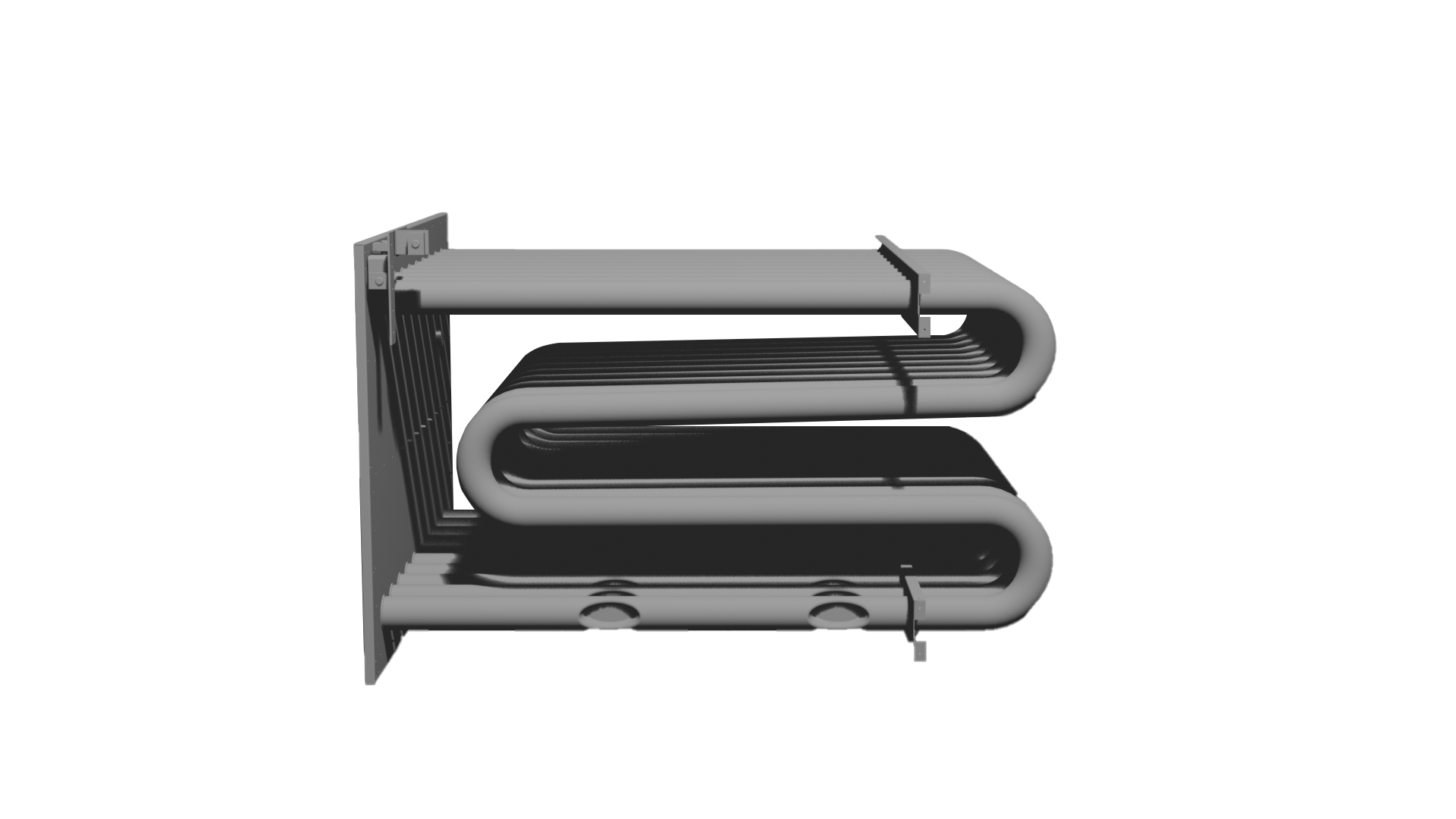

Indirect Gas Fired Burners

Scalable and Flexible Solutions: Designed to handle varying load sizes, the kilns can be easily scaled up or down, making them ideal for operations of any size.

Durable, Long-Lasting Construction: Built with premium stainless steel and aluminum components, Nyle’s kilns are engineered for longevity, providing a reliable, maintenance-friendly solution for long-term success.

Ease of Maintenance: We understand the importance of uptime. That's why our kilns are engineered for simplicity, offering easy access for cleaning and maintenance. Reduce downtime and keep your operations running smoothly with Nyle.